Refractory Boiler Bed Materials

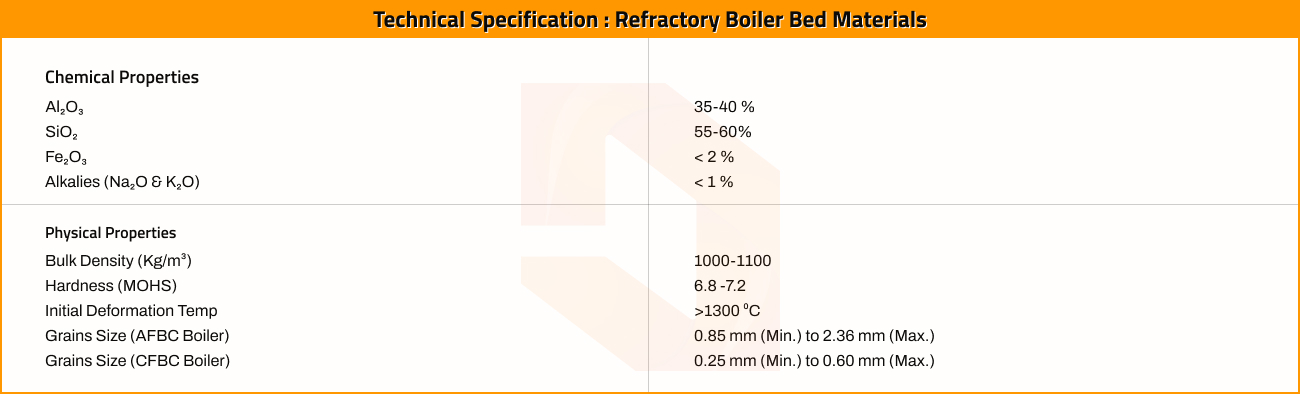

Janta Overseas is a reputable manufacturer and exporter of High-Performance Refractory Boiler Bed Materials from Wankaner, Gujarat, India . Our boiler bed materials are manufactured for optimal performance in high-temperature environments. They are characterized by their low ferric content, high temperature resistance, and the absence of impurities. These materials are crafted from high-quality refractory aggregates with dense textures and high alumina content.

The selection of our raw materials directly influences the reduction of clinker formation. The Boiler Bed Material's specialized properties are instrumental in achieving superior fluidization in boilers such as Fluidized Bed Combustion Boilers (FBC) and Circulating Fluidized Bed Combustion Boilers (CFBC).

The Refractory Bed Material in a CFB boiler is a refractory, non-combustible granular medium composed of limestone, recycled ash, and aggregates like silica sand or specialized refractory materials. It plays a vital role in heat storage, temperature control, and Sulfur capture. The bed material's properties, specifically its density and size, have a significant impact on the fluidization process within all FB reactors.

In a DFB gasification system, the circulating bed materials play a crucial role in transferring energy during the system's endothermic and exothermic reactions, these are often referred to as heat carriers.

High-performance magnetic separators are utilized to isolate and remove any remaining iron particles from materials. Although the material is manufactured in accordance with general guidelines. The particle size distribution can be tailored to specific applications.

Features

- Ideal Distribution of Particle Sizes

- High Resistant Against Clinker Formation

- Excellent for Achieving a smooth Fluidization.

- Accurately Screened Material Free From Dust and Fines

- High Initial Deformation Temperature

- Low Alkali Content