Calcium Silicate Blocks

Janta Overseas, a leading manufacturer and exporter of calcium silicate boards, delivers high-performance products with superior mechanical and thermal characteristics. These rigid boards are designed for high-temperature applications, including furnaces of all types, and function effectively as a thin insulation lining when combined with lightweight refractory bricks or concrete.

Calcium silicate boards exhibit exceptional structural integrity, low thermal conductivity, and resistance to chemical and moisture degradation. Their inherent moisture-resistant and thermal insulating properties contribute to environmental protection.

The product's primary raw materials consist of silica dioxide (SiO2), calcium oxide (CaO), and natural wood fibers, which serve as reinforcing agents. These materials are combined with other components to achieve optimal performance. It is a high-performance, energy-efficient material with superior heat resistance.

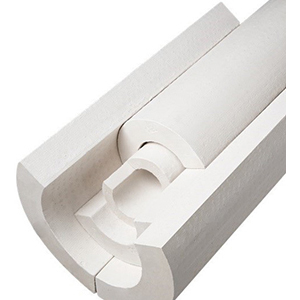

We provide a diverse range of calcium silicate boards and pipes, including both medium and large sizes, tailored for specific applications and featuring varying densities and temperature grades. In addition to the boards, our Calcium Silicate materials come in clean, manageable, and easily installable pipe sections, segments, and cut sections.

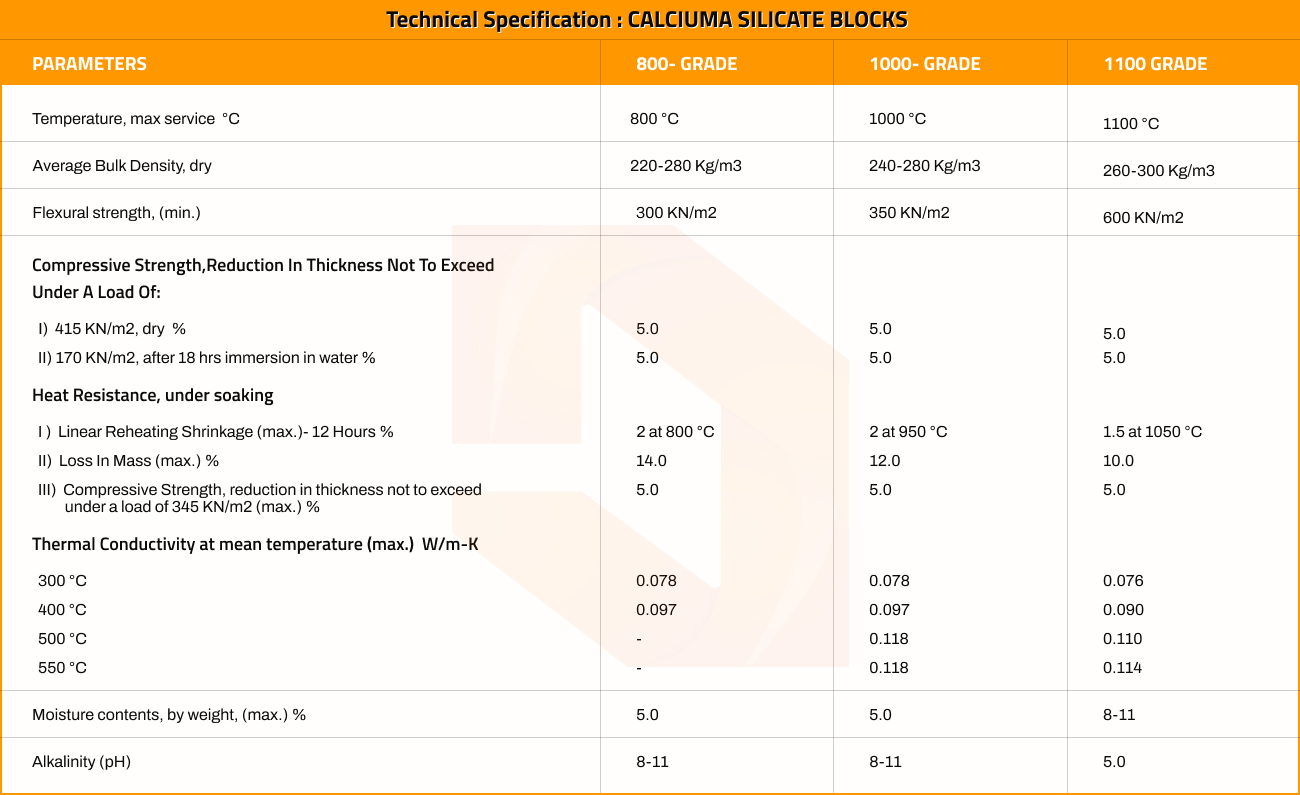

Calcium Silicate Blocks

*Tested in accordance with BS-874 Cold Face 40 deg. C. Also as per IS 9490, water calorimeter apparatus.

PARAMETERS

800- GRADE

1000- GRADE

1100 GRADE

PARAMETERS

Temperature, max service °C

800- GRADE

800 °C

1000- GRADE

1000 °C

1100 GRADE

1100 °C

PARAMETERS

Average Bulk Density, dry

800- GRADE

220-280 Kg/m3

1000- GRADE

240-280 Kg/m3

1100 GRADE

260-300 Kg/m3

PARAMETERS

Flexural strength, (min.)

800- GRADE

300 KN/m2

1000- GRADE

350 KN/m2

1100 GRADE

600 KN/m2

PARAMETERS

Compressive Strength,reduction in thickness not to exceed under a load of:

800- GRADE

1000- GRADE

1100 GRADE

PARAMETERS

Compressive Strength,reduction in thickness not to exceed under a load of:

I) 415 KN/m2, dry %

800- GRADE

5.0

1000- GRADE

5.0

1100 GRADE

5.0

PARAMETERS

Compressive Strength,reduction in thickness not to exceed under a load of:

II) 170 KN/m2, after 18 hrs immersion in water %

800- GRADE

5.0

1000- GRADE

5.0

1100 GRADE

5.0

PARAMETERS

Heat Resistance, under soaking

800- GRADE

1000- GRADE

1100 GRADE

PARAMETERS

Heat Resistance, under soaking

I ) Linear Reheating Shrinkage (max.)- 12 Hours %

800- GRADE

2 at 800 °C

1000- GRADE

2 at 950 °C

1100 GRADE

1.5 at 1050 °C

PARAMETERS

Heat Resistance, under soaking

II) Loss In Mass (max.) %

800- GRADE

14.0

1000- GRADE

12.0

1100 GRADE

10.0

PARAMETERS

Heat Resistance, under soaking

III) Compressive Strength, reduction in thickness not to exceed under a load of 345 KN/m2 (max.) %

800- GRADE

5.0

1000- GRADE

5.0

1100 GRADE

5.0

PARAMETERS

Thermal Conductivity at mean temperature (max.) W/m-K

800- GRADE

1000- GRADE

1100 GRADE

PARAMETERS

Thermal Conductivity at mean temperature (max.) W/m-K

300 °C

800- GRADE

0.078

1000- GRADE

0.078

1100 GRADE

0.076

PARAMETERS

Thermal Conductivity at mean temperature (max.) W/m-K

400 °C

800- GRADE

0.097

1000- GRADE

0.097

1100 GRADE

0.09

PARAMETERS

Thermal Conductivity at mean temperature (max.) W/m-K

500 °C

800- GRADE

-

1000- GRADE

0.118

1100 GRADE

0.11

PARAMETERS

Thermal Conductivity at mean temperature (max.) W/m-K

550 °C

800- GRADE

-

1000- GRADE

-

1100 GRADE

0.114

PARAMETERS

Moisture contents, by weight, (max.) %

800- GRADE

5.0

1000- GRADE

5.0

1100 GRADE

5.0

PARAMETERS

Alkalinity (pH)

800- GRADE

8-11

1000- GRADE

8-11

1100 GRADE

8-11

Availability Grades & Sizes

800 0C, 1000 0C & 1100 0C.

600x150mm, 600x300mm, 600x600 mm, 600x225mm.

500x500 mm, 1000x500 mm, 1000x600mm, 900x600mm, 500x500mm.

1200x2400mm, 1200x1200mm, 1200x1000mm.

Features

- High mechanical strength.

- Low thermal conductivity.

- Resistant to moisture and chemicals.

- Excellent machinability to close tolerances.

- Dust free surface & Asbestos free.

- High electrical strength.

- High arc resistance.

Area of Application

- Heat protection, Load-bearing pipe columns.

- Dryer, ventilation and air conditioning technology.

- Insulating cut sections for industrial applications.

- Special applications for the construction of fireplaces.

- Furnace construction, special parts for induction furnaces.

- Machine and apparatus construction.

- Precision parts for machine and apparatus construction.

- Thermal and electrical insulation, Arc chutes.

- Oven and drier walls/cladding, Platen press insulation, Load bearing pipe supports.

- Heat shields, Thermal breaks, Furnace bottom.

- Working lining in low energy aluminium die cast holding.